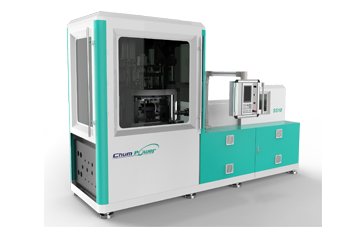

Fully Electric PET stretch blow molding Machine - L Series

All-Electric PET Bottle Injection Blow Moulding Machine Manufacturers

CHUMPOWER MACHINERY CORP. was founded 35 years ago and is the largest manufacturer of dual-axis PET stretch blow molding machines. Aiming at a trend in the PET industry, L Series High Productivity PET stretch blow molding Machine was developed which has multiple advantages of being speedy, stable, power-saving, widely acceptable, and embedded with blow-fill-cap capability.

This know-how can be extended to the entire series of PET stretch blow molding machines and can be utilized vertically for applications with medium-to-high capacities. 12 patents have been obtained in Taiwan, the USA, and Italy.

The all-electric linear design going with the production of lightweight bottles can reduce 20% of bottle weight. The unique seal design is utilizing the theory of pressure to maintain the form of cap thread without distortion during blowing. The heating system, focusing on lightweight cap thread, is equipped with an independent cooling system for the prevention of distortion caused by overheating on the cap thread.

There is an air recycling device for the re-use of high-pressure air within the blowing molding machine for further conversion to be supplied to pneumatic tanks of each unit. Also, we programmed the best permutation and combination of heating and reflection boxes which can save 30%~35% of energy waste compared with conventional linear PET blowing machines.

L Series of CHUMPOWER has a mechanical structure design for high capacity. A 6-axis servo motion control is used to elevate the capacity by up to 10%. Coordinating with the BECKHOFF system from Germany with effective control over the co-motion of multiple shafts, redundant waiting time can be mitigated and goals of elevating capacity, stability, and safety can be achieved. Also, remote CCTV is available to increase service quality, reduce production costs, and improve efficiency.

All-Electric Linear Blow Molding Machine: L-S8 Series

This machine features a simple structure with extremely high capacity and can be linked with a filling machine to become a blow-fill-cap production line. It is ideal for production lines with medium-to-high capacity and highly cost-effective is guaranteed.

- Maximum Capacity of PET Container: 2 liters.

- Maximum Capacity: 12,000 (bottles/hour) (0.6 liters).

- Power Consumption: 44.2-kilowatt hour (0.6 liters).

- * 23.8-kilowatt-hour saved compared with conventional machines.

- Air Consumption: 9,100 liters/minute (0.6 sec).

拷貝.jpg?eqg6auyjuf)

Welcome to Contact Us!