Introduction to Chuck Systems

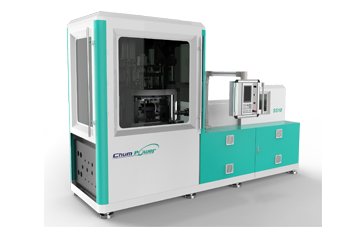

CHUMPOWER has a comprehensive and diverse range of tooling chucks, including the five major series of Keyless, Keytype, Hex key drill chuck, EXpower Universal Chuck, and Tap Chuck, which can be used in conjunction with manual or automatic chuck tools in metal processing, wood processing, food, and medical applications.

Keyless series is designed to allow easy operation, allowing fastening by hand or with a wrench. It offers high precision, rapid tool swapping, and allows use with tools, such as assembly chucks, drill chucks, reamer, milling chuck, and tool bits. Manufactured in accordance with JIS, DIN, ISO, and ANSI international specifications, the series can be used with the assembly tooling chucks for application in the CNC tool swapping system and traditional machine tool. Besides applications in various CNC machines, the stainless steel chuck can also be used in food and medical applications.

Keytype series is designed to be light and flexible, and the chuck can be secured manually with a T-wrench. The series offers high precision and rapid tool swapping, and it is favored by pneumatic manual machine tool and traditional tool manufacturers.

HEX KEY DRILL CHUCK is designed in accordance with JIS, DIN, ISO, and ANSI international specifications. Used in CNC tool swapping systems, the assembly tool chuck can be used with drill chucks, reamers, milling chucks, tool bits, and tap chucks. It is applicable at medium and high speed rotations, offering excellent torque and easy operation, as well as allowing coolant through the center trough.

EX-POWER Universal Chuck series is internationally patented by CHUMPOWER as the only chuck series in the industry to allow both clockwise and counterclockwise rotation. It can be used with various tools and is designed according to JIS, DIN, ISO, and ANSI international specifications. When combined with the use of integral tools or assembly chucks, it can be used in CNC tool swapping systems and traditional machine tools. The strong gripping force, high precision, and integral tool and chuck system allow the series to have high rigidity for use in heavy cutting industrial applications.

Tap Chuck series is further classified into the length

compensation model and torque model. The Tap Chuck length compensation model

can prevent the tap from breaking due to torque overload during tapping. The

extra length can increase the buffer distance, which is suitable for tapping in

deep bore workpieces. The Tap Chuck torque model has increased torque and

rigidity which can prevent damage to the workpieces and tools, allowing

extended Tap Chuck life.

*If the Tap specifications do not

match, please take note if the diameter of the Tap Chuck and the dimensions of

the square bore match with the tool during selection.