Drill chuck operation instructions

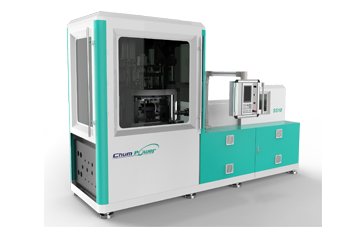

CHUMPOWER drill chuck is quick, convenient and easy to operate and extremely safe. It is suitable for CNC tool system of integrated machining center. It can be used with drills, reamers, mill, lathe cutter, tapper and other types of tools. The selection of chucks must refer to the size of claws first and then the gripping depth if tools are inserted in the chuck.

The drill chuck uses the hex wrench to drive the bevel gear next to the chuck to hold the tool. Reversing the hex wrench can open three jaws. Forwarding the hex wrench can close three jaws.

Installation and fixation steps are as follows:

1. Open three jaws of the chuck wide enough to put in the tool.

2. Forwarding the hex wrench so that the chuck can drill the tool tight.

3. Then the drill chuck can start processing.

4. Reverse the hex wrench to loosen and remove tools.

In order to reduce accidents and extend the using life of chucks and tools, insert the tool shank to the deepest bottom, or at least 2/3 of the jaw length (L). Operators should not wear cotton gloves. If the hands are too greasy, please wipe them clean before using the chuck. CHUMPOWER drill chucks lock the hexagonal hole of the driving gear through driving gear. If the locking force exceeds 260 kgf.cm ↑, it will cause damage to products. Besides, during inspecting, clamp torque bar or those of other specifications must have at least 35L bearing surface so that the test value will be stable.