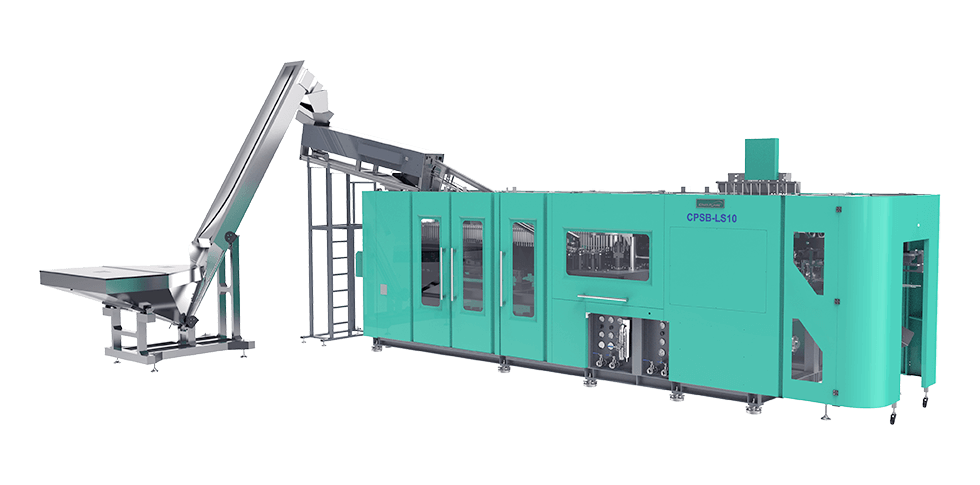

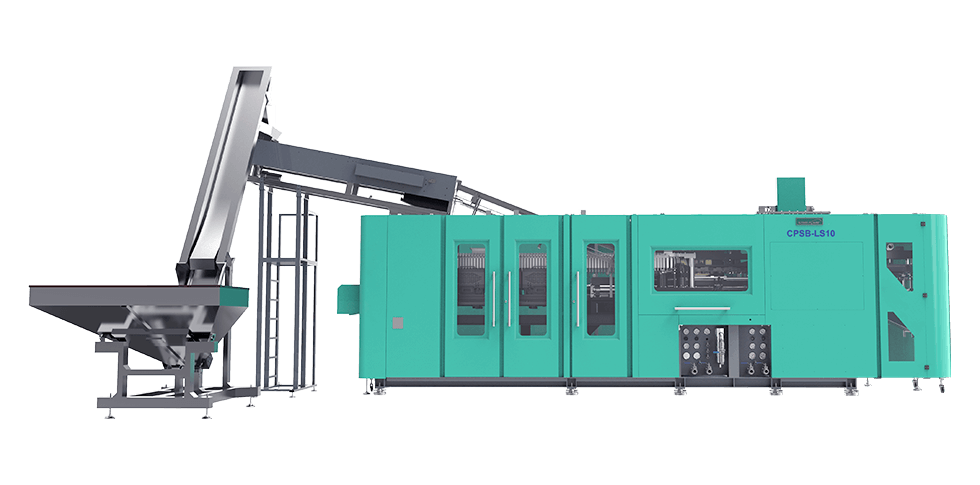

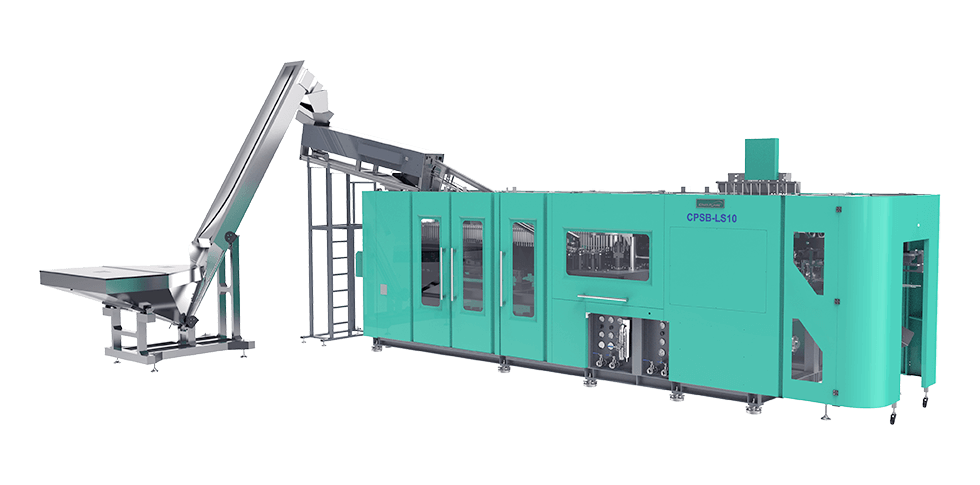

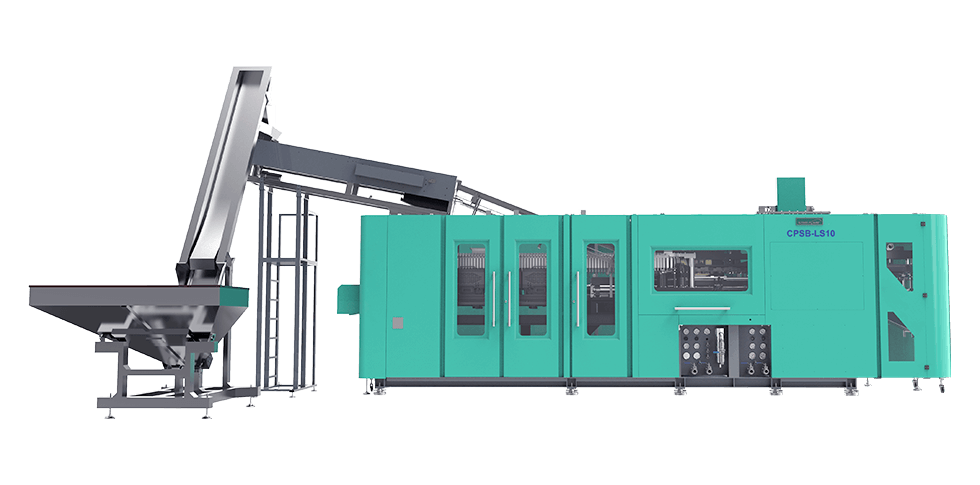

L Series

Linear Stretch PET stretch blow molding Machine

Max.capacity

60ML-20L

OUTPUT BPH

200~24000

Cavity

1~14

Dual-axis extension blow molding machine

- Can be connected to filling machine to form a blowing, filling, and capping production line.

- Suitable for application in medium – high productivity production lines

- Recycling system reduces the consumption of high pressure gases.

FEATURES

Feeding System

- The entire series is fixated on the machine to reduce machine configuration space.

- The preform infeed system has multiple levels of protection system to ensure precise preform infeed and zero deficient products.

- Uses continuous preform infeed system.

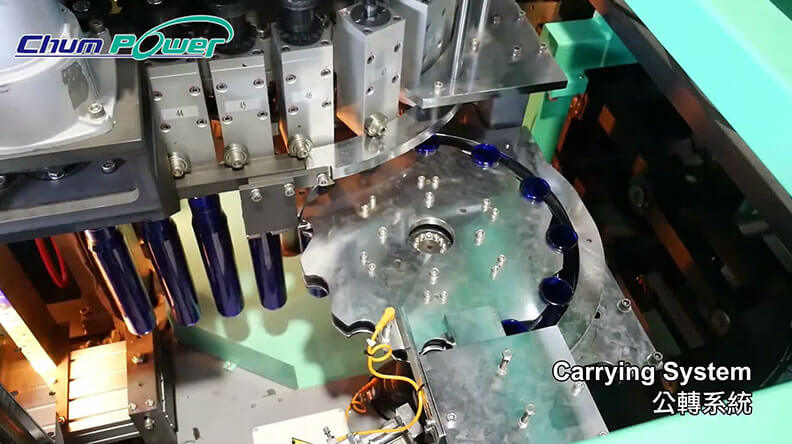

Carrying System

- Effectively reduces heating distance, energy consumption, and increases heating efficiency.

- Horizontal level configuration; preform does not have to be turned; simple structure

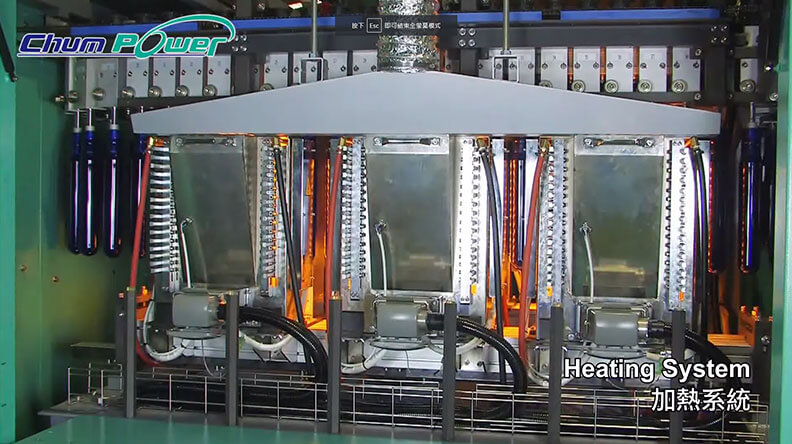

Heating System

- When replacing the lamps, the heating oven can be turned over on the machine for maintenance.

- The water pipe directly runs through the heating oven to protect the valve.

- Optimized ventilation system allows cooling of preform surface.

- Preform temperature monitoring functions.

Preform temperature monitoring functions.

- Servo-driven preform transfer system with grippers secured on the timing belt.

- Servo-driven variable pitch system for fast and accurate preform handling between two components.

Blowing and Clamping System

- Servo-driven clamping system with CAM synchronized base mold operation.

Pressure / Blowing System

- Uses a combination of high-speed and precision blowing valves to achieve high productivity

Control System

- Touch-panel interface for easy operation.

- 10.4 inch LCD touch screen with 64K color.

Miscellaneous

- Connected structure in fully electric version ensures high speed operation and precise positioning.

- Uses fast mold replacement structure.

- Low energy consumption, low wear and tear, and low pollution.